Floor Conveyors

Floor conveyor systems are an ideal and efficient way of moving unit items around a facility & whether you are moving small parcels weighing a few grams or a 1500Kg pallet there is a solution for your business.

They are suitable for a wide range of industries and environments and are available as roller, belt or chain variants. Their modular design means they can be implemented to suit your specific requirements.

Powered Roller Conveyors

Brown & Holmes Automation offer a wide variety of powered roller conveyor types for moving and sorting a variety of loads such as parcels, totes and cartons in industries such as warehousing, distribution and logistics. Their robust modular design gives versatility to create systems that satisfy almost any facility.

Lineshaft Conveyor

Lineshaft driven rollers are based on a unique polyurethane belt and roller principle, giving an inherent accumulation characteristic. The modular design that can include bends, switches, 90° chain transfers & stops enables complex systems to be achieved both quickly and cost effectively.

Tote Transportation with Switch Sorter

Tote and Carton Transportation with Divert

Zero Line Pressure Conveyors (ZLP)

These systems are available where delicate handling and/or accurate positioning of items is required. These conveyors are driven via 24v DC powered rollers allowing zones to be created to ensure products stay separated. Dependant on the loads being conveyed the rollers use either round belt or ‘V’ belts to drive the other rollers in the zone. Each roller comes with a programmable control card that with the use of a positioning sensors allows zonal control.

Gravity Conveyors

Gravity roller conveyors (GRC) offer an unrivalled way of moving goods and speeding up production flow all the way from goods-in to goods-out.

We have an extensive range of gravity conveyors available ranging from simple light duty models, up to the heavy-duty range.

As well as the wide range of sizes, the systems are available with high-impact plastic rollers, plastic ‘skate’ wheels or extra heavy-duty steel rollers.

Standard Gravity Roller Conveyor

Flexible Conveyors

The extendable gravity conveyor is ideal for conveying loads in a production assembly plant, warehouse or between loading points. Virtually any shape of conveyor track can be achieved.

The units are both lightweight and manoeuvrable and can be simply folded away when not in use. Available in varying track widths and lengths, with a choice of rollers or wheels, the flexible conveyor is a low maintenance and versatile gravity conveyor.

Telescopic Gravity Roller Conveyors

This type of conveyor is ideal for transferring loads between vehicles or for use in warehouse and production areas.

Available in two standard widths (450mm and 600mm) and in two, three or four-section versions, it has scissor-jack adjustable height ‘H’ section supports, with heavy-duty castors.

Heavy Duty Gravity Roller Conveyors

Designed specifically to meet the specialist needs of the woodworking and panel industries, heavy duty gravity roller conveyors are also suitable for other high specification applications.

Comprising steel rollers fitted with high quality precision bearings mounted in robust angle side frames, the heavy-duty gravity roller conveyors have a wide range of support stands, turntables and mobile trolleys.

Belt Conveyors

Available as either straights or bends, belt conveyors offer a simple reliable method of transporting a large variety of products. They can be arranged horizontally or inclined to move between levels using either incline or spiral belts.

Finished in either mild steel (standard) or stainless steel, they come in a variety of belt widths and are easily integrated with other types of conveyors.

Incline Belt Conveyors

Horizontal Belt Conveyor

Belt curves

These are available in virtually any configuration and are ideal for general purpose use including food applications. A positive chain drive prevents belt slip and products are conveyed with a smooth, positive and even movement.

Spiral Belts

They offer a reliable, continuous transportation system between levels with minimum footprint. Tailored to requirements, they provide an easily maintained alternative to ordinary vertical inclined belt systems.

Vehicle Loaders

Telescopic Booms (Vehicle Loaders)

Available in various extension lengths to suit vehicle trailers up to 40’. The 800mm wide continuous belt allows loading or unloading to take place with constant adjustment of reach depth and working height inside the vehicle via operator push buttons on the boom end.

A vehicle loader is used to make vehicle loading and unloading quick and easy. It can either be specified for a fixed location or mobile, for maximum flexibility.

They are suitable for any industry where loading and unloading of loose parcels & packages occurs.

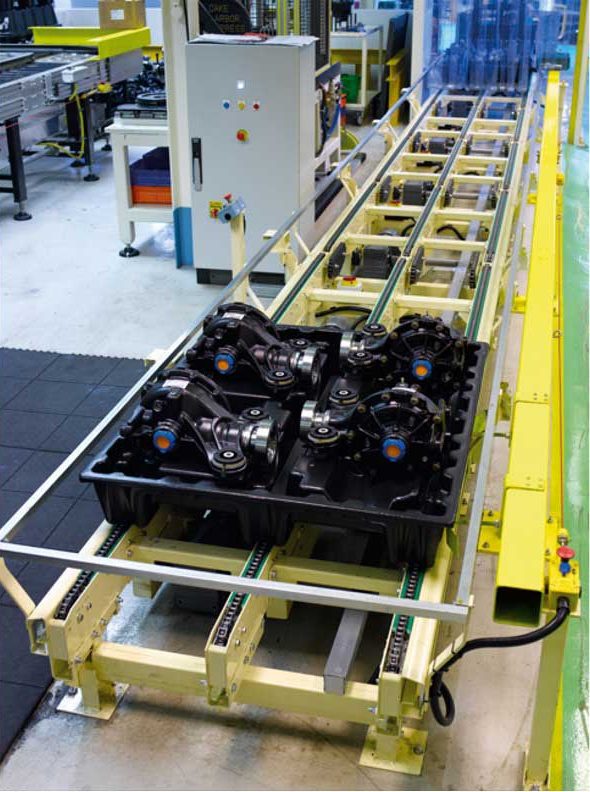

Chain Conveyors

Normally floor mounted, a chain conveyor transports products from one place to another. They can handle heavy products (1500Kg) but work in a horizontal straight line. They are available in various lengths and chain sizes dependant on the application and typical variations are twin strand or triple strand depending on the width of the load and support required.

A chain conveyor has no tracking problems & is extremely durable.

Short sections of chain conveyors are often used as a chain transfer mechanism as part of a larger conveying system. These chain transfers are frequently installed to move totes or pallets at right angles from a roller conveyor or for moving pallets in a different orientation to a roller conveyor. Chain conveyors can also be used when the underside of a pallet is not suitable for rollers.

Triple chain conveyor

Pallet Conveyors

A pallet conveyor is a heavy-duty materials handling system used to carry large or heavy products on pallets. It is a durable and versatile transportation device that can move a wide variety of load weights and sizes with relatively high throughput rates.

The versatility of the pallets allows them to be used in almost any industry as they can be adapted to various shapes and sizes, reaching nominal roller speeds of up to 10 -12m per minute. Throughput rates of the pallets are determined by the user, as it is dependent on the spacing between pallets whilst on the conveyor.

Whether used as simple gravity storage lanes, in-feed and out-feed lanes to other machinery and strappers or as an integrated handling system, pallet conveyors provide a cost-effective alternative to forklift trucks. Empty pallet return conveyor systems are also available. These are usually the same type of conveyor but either built to run on a separate loop or running underneath, the main line using twin levels.

The amount of material a pallet can hold is set by the pallet itself with 1200mm x 1000mm being the largest standard size, however, bespoke solutions can be created. The height of materials used on a pallet conveyor can almost be unlimited but standard heights within the industry are 1000mm and 1800m. The maximum weight used on a pallet conveyor is 1500kg per pallet.

Pallet conveyor is available in gravity and powered versions and can be manufactured using rollers or chains.

Turntables, chain transfers and transfer cars can be used to create a bespoke system.

Also available are pallet dispensers/stackers that can be either floor mounted as a stand-alone unit, or they can be positioned over a pallet conveyor system.

Pallet Conveyor (Roller) Loading

Pallet Conveyor (Turntable)

Single Cask transfer – Cooperage (Cross transfer units)

As well as the transportation of traditional pallets Brown & Holmes Automation can also provide conveyor systems for the transportation of both palletised and loose casks. These conveyors can be for Cooperage applications such as moving empty single casks or alternatively for filling and disgorging solutions where the pallet conveyors, controls and installation must adhere to stringent ATEX requirements.

Brown & Holmes Automation would be happy to discuss your requirements.