Bespoke Materials Handling

Bespoke Materials Handling covers a range of solutions that standard conveyors or handling solution are not suitable for. These are systems that are created to deal with unique requirements, be that due to size, weight, process requirement or space restrictions.

They can be incorporated into a variety of industries including heavy engineering, automotive, aerospace and food and beverage.

Towline Conveyors

A towline system is a transportation conveyor that runs along the ground and tows a series of product trolleys in a straight line through a production or assembly process. The towline conveyor can be mounted either on the floor or, should a flush floor be required, it can be mounted within a pit using floor plates to cover the gap.

Towline conveyors can be engineered to utilise bi-planar chain, precision chain or heavy-duty fabricated chains depending on the weight being towed.

Towline Conveyor Layout Design

This can be tailored to accommodate the needs of the factory space and process & it can either run in a single straight line or in a loop. Depending on the process required, the operation can be continuously slow moving or it can be indexing (stop/start).

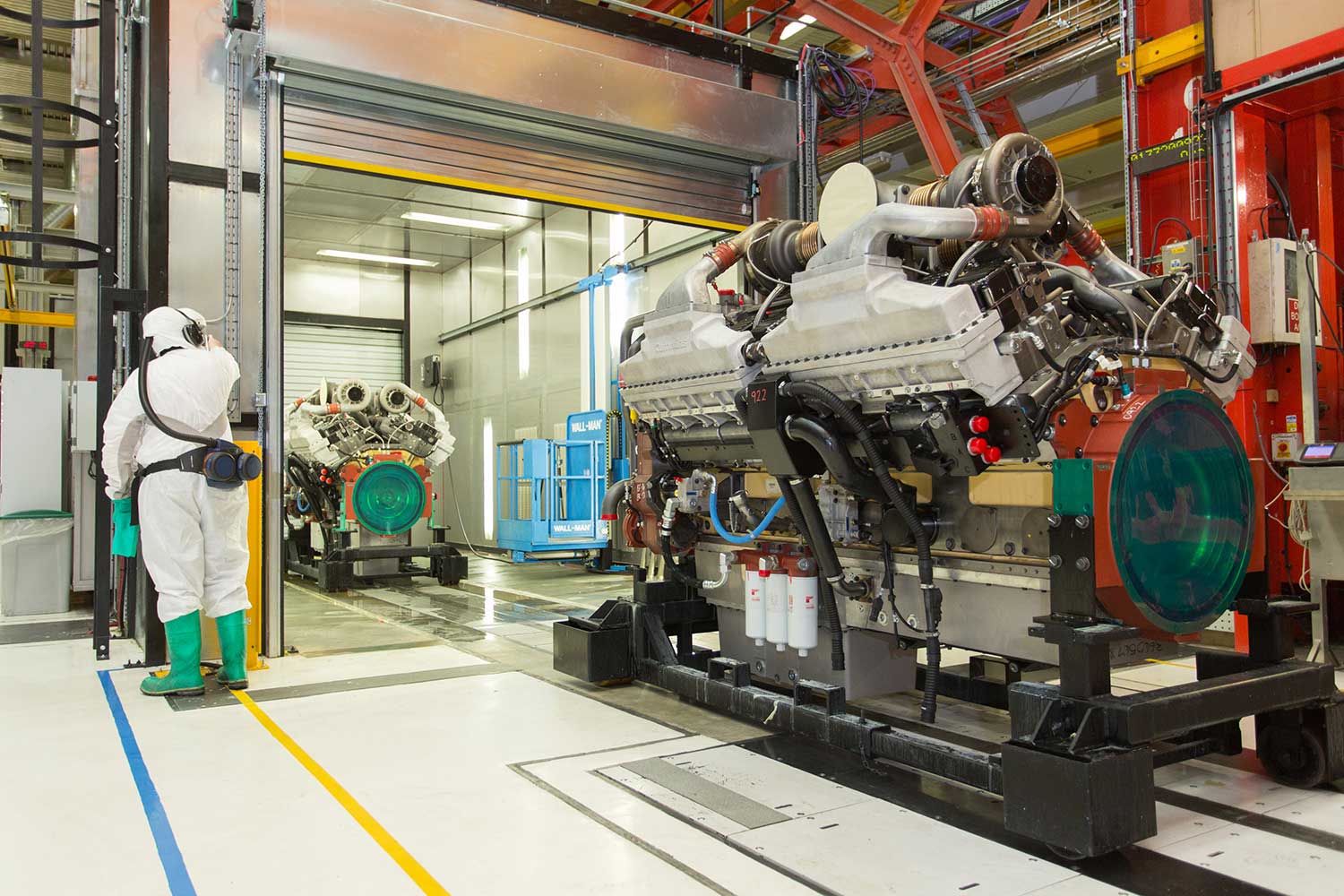

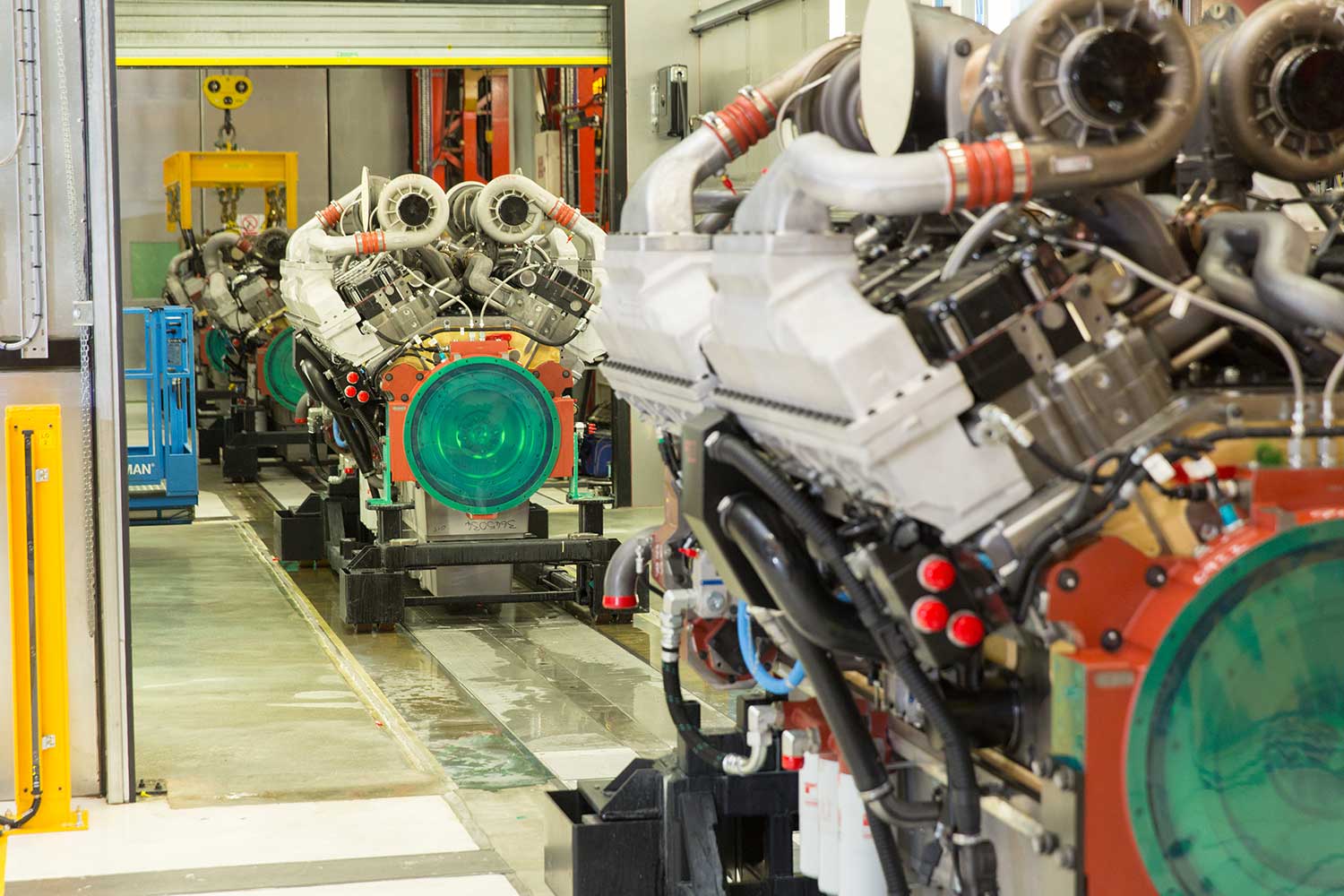

A trolley can be designed to transport a variety of components such as dashboards, axles, large diesel engines to 16 tonne earth moving vehicles.

Heavy Duty Towline

Heavy Duty Towline

Slat Conveyors

Slat conveyors comprise of fixed plates mounted between two chains effectively creating a continuous surface. They can be mounted either on the floor or if a flush finish is required, they can be mounted within a pit. Products can be carried at a fixed pitch either directly on the slats or on jigs.

They move in a straight line, and they can be continuously running or alternatively indexing (stop/start).

Dependent upon the product being transported they can be single or double slat with overall widths designed to suit the particular application.

Options are also available on the slats themselves, they can be steel or plastic, drop slats are also available for automotive applications.

Special Engineered Solutions

Special Engineered Solutions are available from Brown & Holmes Automation, and they are uniquely design solutions to solve a specific challenge.

Brown & Holmes has a long history with the manufacture of bespoke engineered parts and would be happy to discuss any projects that require a solution that is outside of ‘Standard’

Engine Block Rollover