Robotics & Automation

Robotics and Automation are now an everyday part of life and can transform a process or business, but it is essential to get it right. At Brown & Holmes Automation, we believe that it is crucial to have an automated solution that is right and tailor made for you, so our aim is to work and collaborate together with our clients, to understand their needs and deliver solutions that give the best results for their business, & future proofed to support your business as it evolves and grows.

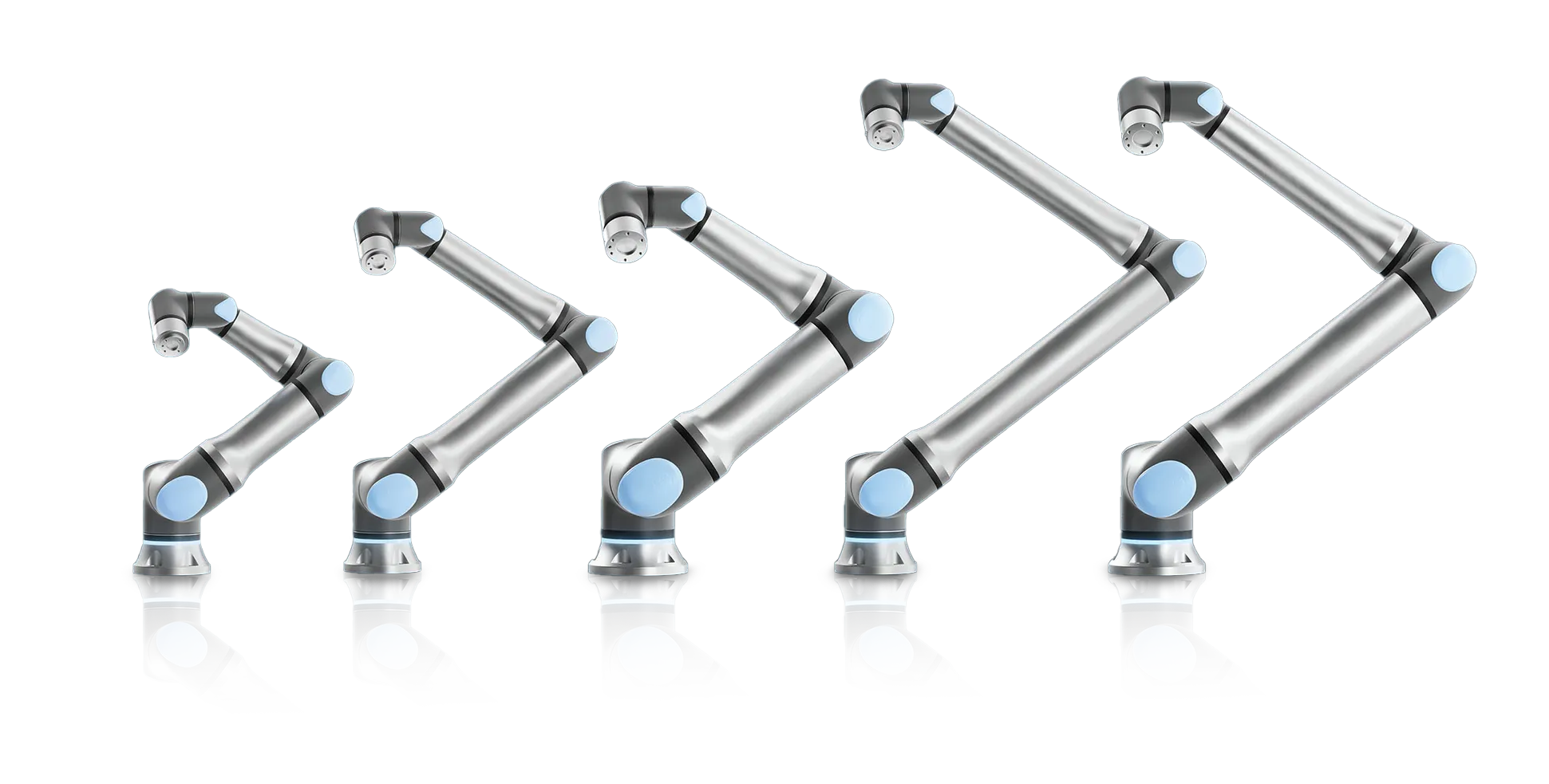

Robotics

Brown & Holmes Automation can provide robotic solutions for a wide spectrum of industries, for performing tasks to improve production processes and safety while increasing productivity and efficiency. They can undertake repetitive activities that keep operators from being utilised for more effective tasks, carry out loading & unloading operations to provide safer working environments for your operators, offer repeatability that minimises errors and reduces scrap and costs.

Palletising/Depalletizing

Industrial and Collaborative robot options are available from Brown & Holmes Automation for use in Palletising and Depalletising processes. Our solutions can be provided as a stand-alone cell or as an automated solution utilising conveyors to move products. Not only do these solutions provide efficiency savings but offer an increase level of health and safety for operators due to the reduction in manual handling.

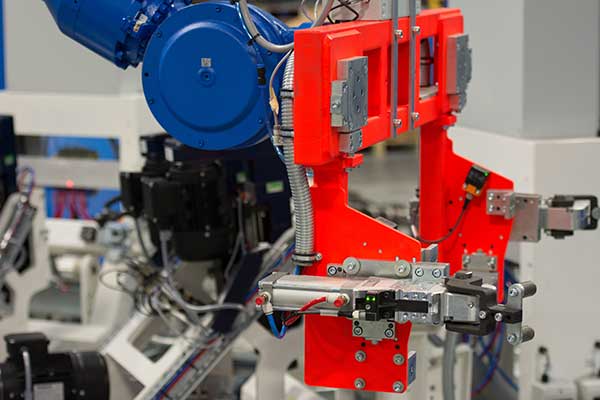

CNC Machine Tending

The manual loading and unloading of a machine tool by operators for several hours at a time can lead to errors through fatigue which increases inefficiencies and scrap and ultimately costs. Using a robot solution for CNC machine tending offers many benefits such as consistent repeatability of loading and unloading, better utilisation of operators and ultimately reduced costs.

Industrial robot options are available as are Cobot options – Subject to the operating conditions the Cobot option can allow greater flexibility for operators and robots to work together.

Automated Machines

Brown & Holmes Automation can provide a range of machines and assembly stations that can be used for product specific manufacturing and assembly tasks. Technology such as Vision Systems, RFID, barcode scanning and Pick by Light can be incorporated where required to support the process and aid with traceability and vital production data.

These solutions offer the following benefits –

- Enhanced compliance, quality and accuracy

- Increased capacity and productivity

- Improved working environment

- Reduced labour strain

- Operational data

Mould Cleaning

The Brown & Holmes Automation automatic mould cleaning machines increase efficiency and improve the process of mould cleaning, reducing costly scrappage rates.

Benefits

- Enhanced compliance, quality and accuracy

- Increased capacity and productivity

- Improved working environment

- Reduced labour strain.

Features

- Individual mould variance manipulation programs

- Fully enclosed industrial extraction system captures mould debris

- Debris visual monitoring system determines mould cleanliness.

Assembly Stations

Brown & Holmes Automation can provide a range of automated assembly station solutions

Benefits

- Enhanced compliance, quality and accuracy

- Increased capacity and productivity

- Improved working environment

- Reduced labour strain.

Features

- Ergonomic operator height adjustment

- Soft edge tooling

- Inspection grade lighting.

Pallet Stacker

Our innovative pallet stacker means fewer forklift truck movements and reduced manual handling risks for operators. Without doubt one of the most robust & reliable units available on the market, so it is built for use in the most challenging environments.

Benefits

- A 10 second cycle with up to six individual pallets per minute stacked or de-stacked, with a standard capacity of 10 pallets

- 24-hour operation to meet requirements of large distribution warehouse facilities

- Mesh peripheral guarding around the pallet stacker allows the user to see the pallets in the unit

- Interlocked light guards on the pallet load/unload access meet necessary safety requirements

- UKCA/CE Marked.

Features

- Interlocked light guards on the pallet load/unload access meet necessary safety requirements

- Stack or de-stack mode

- Presents single pallet to operator